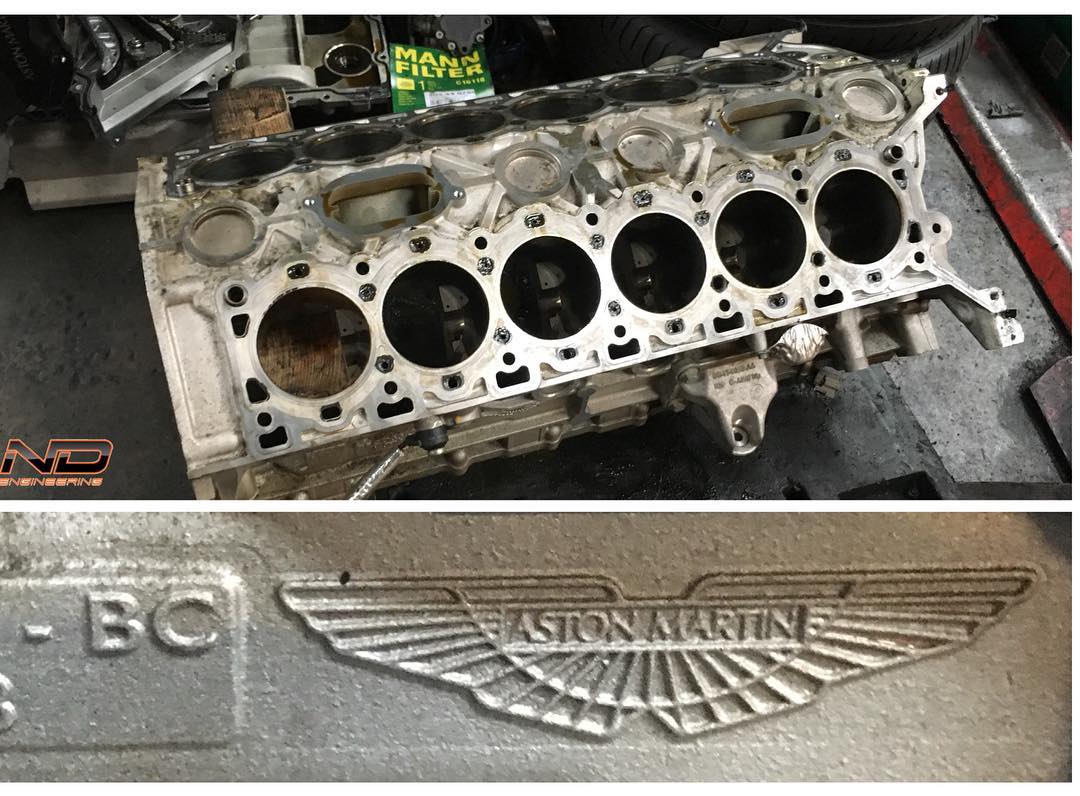

The Aston Martin V12 engine block is a high-performance engine block used in various Aston Martin models, including the DB11, DBS Superleggera, and the Vanquish. The V12 engine is known for its power, smoothness, and distinctive sound

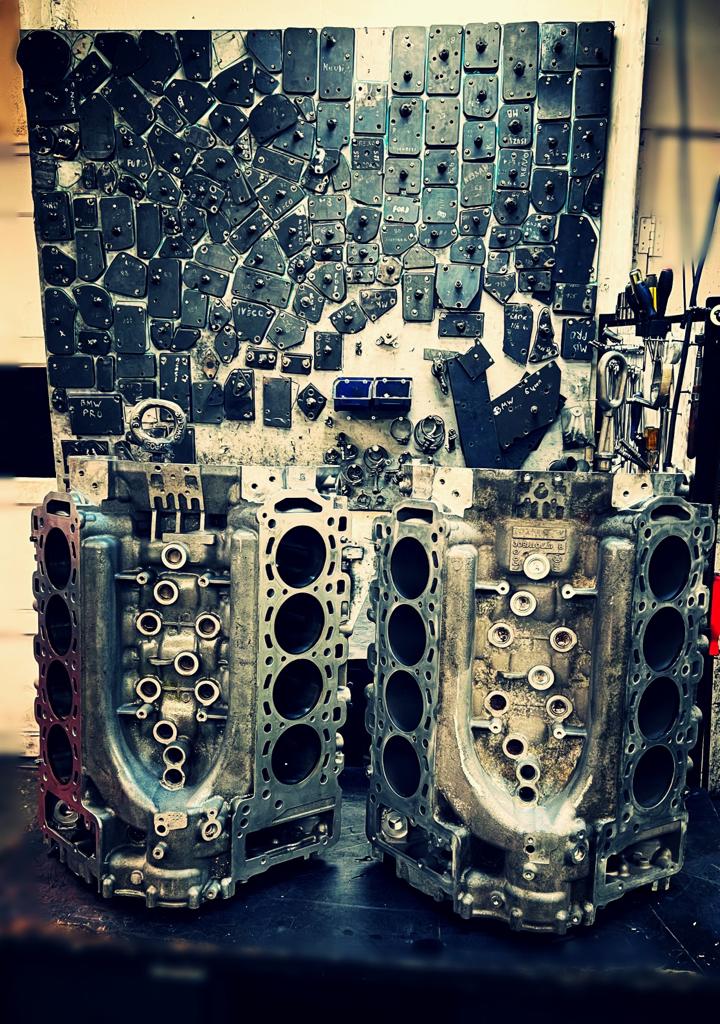

Repairing a V8 cylinder block can be a complex and challenging task, depending on the extent of the damage. Here are some general steps involved in repairing a V8 cylinder block:

- Inspection: The first step is to thoroughly inspect the cylinder block to identify the extent of the damage. This may involve visual inspection, pressure testing, and possibly even X-rays to detect cracks or other issues.

- Cleaning: Before any repair work can begin, the cylinder block needs to be thoroughly cleaned to remove any dirt, oil, or debris that may interfere with the repair process.

- Repairing Cracks: If the cylinder block has cracks, they will need to be repaired. This can involve techniques such as welding, stitching, or using specialized crack repair kits.

- Boring and Honing: If the cylinder bores are damaged or worn, they may need to be bored out and honed to restore them to the correct size and finish.

- Resurfacing: The deck surface of the cylinder block may need to be resurfaced to ensure a proper seal with the cylinder head.

- Thread Repair: If any threads in the cylinder block are damaged, they will need to be repaired using thread inserts or other methods.

- Assembly: Once all repairs are complete, the cylinder block can be reassembled with new gaskets, seals, and other components.

It’s important to note that repairing a V8 cylinder block is a job best left to professionals with experience in engine machining and repair. If you’re not comfortable with this level of work, it’s recommended to seek the help of a qualified mechanic or engine builder.

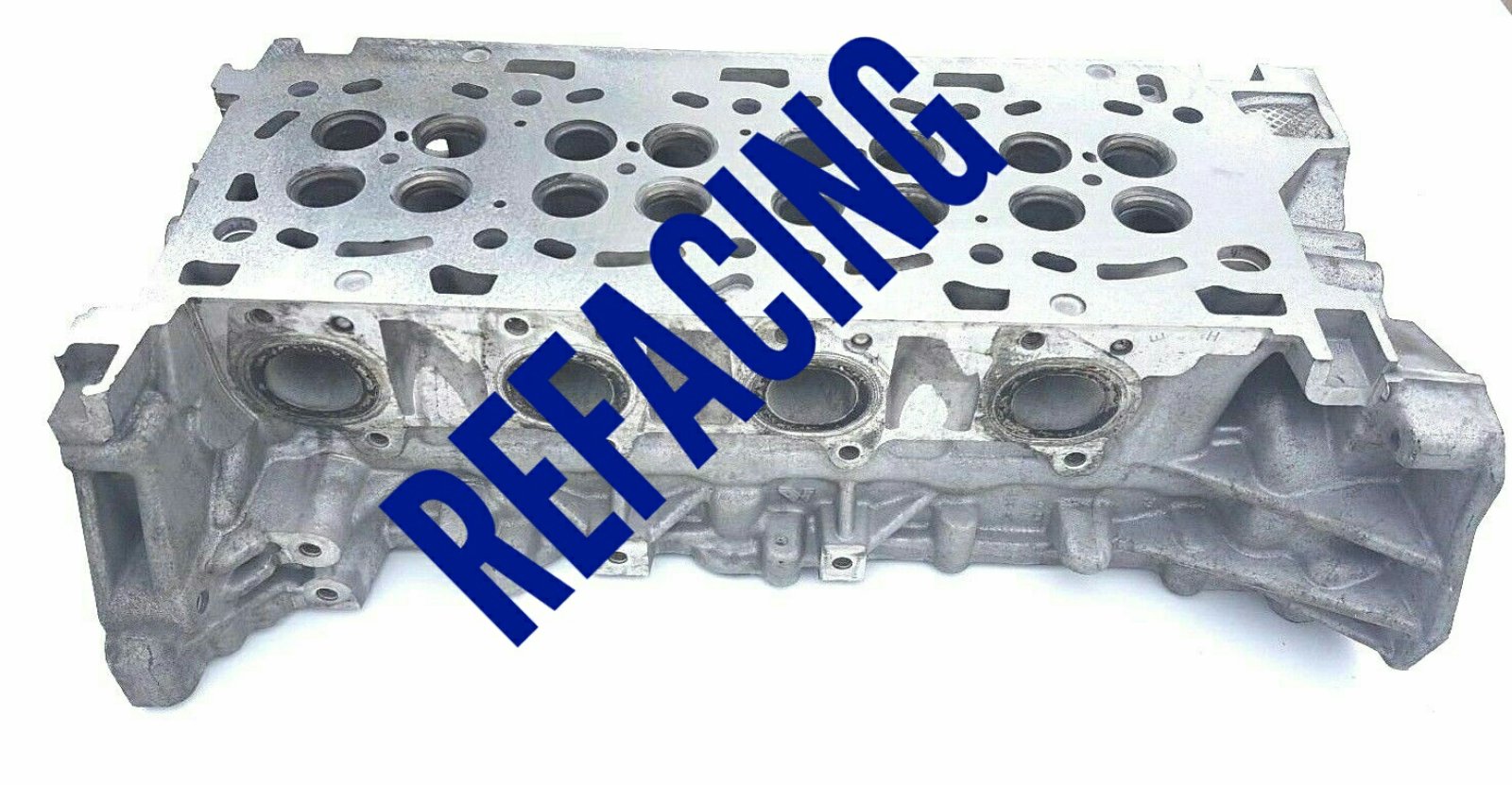

Cylinder head valve seat cutting is a process that involves machining the valve seats in the cylinder head to ensure a proper seal between the valves and the cylinder head. This process is typically done when rebuilding an engine or performing maintenance on the cylinder head.

The valve seat cutting process involves using a specialized cutting tool to remove material from the valve seat area to create a smooth, flat surface that provides a good sealing surface for the valve. This helps to improve engine performance, efficiency, and reliability by ensuring that the valves seal properly and prevent leakage of combustion gases.

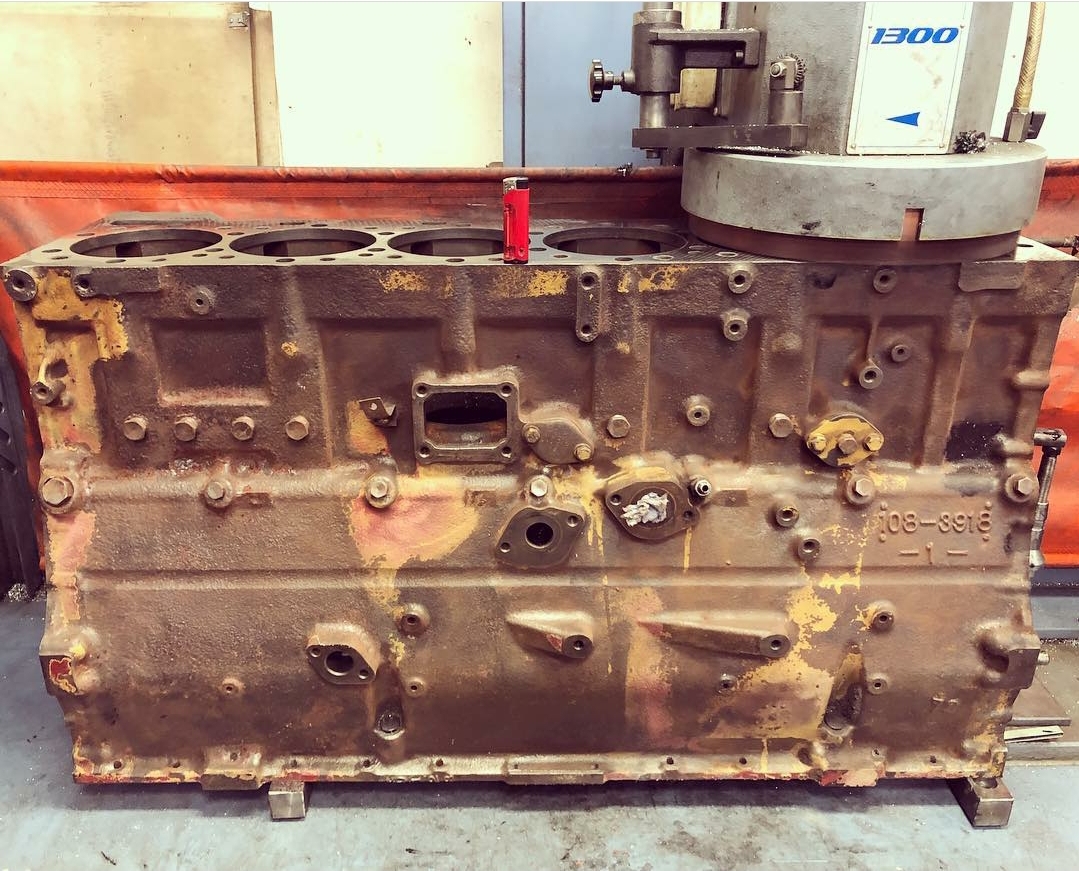

Cylinder block resleeving is a process that involves installing new cylinder sleeves or liners into the engine block to restore the cylinder bores to their original specifications. There are several reasons why cylinder block resleeving may be necessary:

- Cylinder wear: Over time, the cylinder bores in an engine block can wear out due to the constant friction and heat generated by the piston rings. This wear can lead to increased oil consumption, reduced compression, and decreased engine performance. Resleeving the cylinders can restore the proper dimensions and surface finish, allowing for optimal engine operation.

- Cylinder damage: In cases where the cylinder walls have been damaged due to scoring, pitting, or other forms of wear, resleeving can provide a cost-effective solution to repair the damage without having to replace the entire engine block. Installing new sleeves can restore the cylinder bores to like-new condition and prevent further damage to the engine.

- Engine rebuilding: When rebuilding an engine, resleeving the cylinders can be a necessary step to ensure that the engine performs at its best. By installing new sleeves, the engine builder can customize the bore size to accommodate oversized pistons or other performance modifications, resulting in improved power and efficiency.

- Performance upgrades: For high-performance engines or racing applications, resleeving the cylinders may be necessary to accommodate larger pistons or increase the displacement of the engine. By installing custom-made sleeves, engine builders can optimize the performance of the engine and achieve higher horsepower and torque output.